Adiabatic coolers and condensers

More than just air conditioning is usually needed for cooling in industrial processes. Cooling towers were a popular solution in the past, which are usable in our temperature conditions, but consume a large amount of water during their operation, thus creating additional costs and a burden on the environment that could be avoided.

Adiabatic-based coolers and condensers are a great alternative that consumes up to 95% less water. They are also more efficient in heat transfer, have lower maintenance costs and do not have chemicals that could leak into the environment.

Why is a dry cooler not enough?

Dry cooling using fans in our conditions could only be used for about 9 months a year when the outdoor air temperature is lower. Their performance is not sufficient in the summer months. And the warmer the ambient air, the higher the risk of the production technology overheating. This is why dry coolers are unsuitable in our conditions.

How do adiabatic and hybrid coolers work?

The adiabatic cooler works on the basis of adiabatic cooling, which is a thermodynamic process during which temperatures in a closed system are exchanged, ideally without heat leaking into the environment.

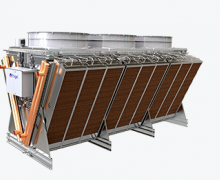

The adiabatic cooler consists of

- water-air heat exchanger, which provides heat transfer between the internal water circuit and the outside air

- axial fan for air supply and cooling

- adiabatic system for better air cooling in warm weather

- control unit that monitors the entire system and supervises its operation.

Thanks to its technology, the adiabatic cooler works the same way as a dry cooler that does not consume any water for most of the year. This is why hybrid coolers are often mentioned. The water in the closed circuit is cooled by fans and is not drained.

However, if the ambient air gets too warm, a dry cooler would not be sufficient. Now it is the time for an adiabatic system that allows the air to cool before it is used in the cooling unit. The control unit ensures that the steam is discharged into the environment only if necessary and the water consumption is as low as possible.

Condenser cooling

If you use steam instead of water in your operation, a condenser must be used to cool it. The steam in a surface condenser is not in direct contact with the environment. Steam condenses on condenser walls that are in contact with the coolant, often directly in the form of ambient air or water. The condenser wall where this heat exchange occurs is called the heat transfer surface. It is often made up of finned pipes, smooth pipes or plates to make great use of the heat transfer surface even with a small volume.

Frigel adiabatic & hybrid coolers

We offer adiabatic coolers by Frigel, an Italian brand that has been operating in the world of cooling equipment since 1960. In the 1980s, it was the first company to come up with its own design of a heat exchange system between coolant and ambient air (Ecodry) and since then, it has continued to develop environment-friendly cooling systems in its inventions.

LU-VE adiabatic coolers and condensers

LU-VE Group is an Italian company that has been focusing on industrial chillers and condensers since 1985. Adiabatic coolers and condensers by LU-VE can cool air, liquid or gas while offering low energy and coolant consumption, leaving only a minimal ecological footprint.

Baltimore Aircoil adiabatic coolers and condensers

Baltimore Aircoil Company (BAC) started as a small business in Baltimore, USA back in 1938. Since then, it has been selling and developing cooling systems for all types of applications, from cooling towers, through coolers to condensers. We offer adiabatic coolers and condensers by Baltimore Aircoil, which are made with both ecology and performance in mind, adapted to your requirements and built in such a way that their maintenance or repair is easy and without unnecessary risks.